Ethoxylation is a chemical process where ethylene oxide reacts with amine, alcohol or phenol, acid, oil to produce ethoxylates or ethoxylated surfactant. It is the most widely practiced Alkoxylation at Venus Goa, which involves the addition of epoxides to these substrates to produce wide range of our ethoxylated products.

Venus Goa manufactures more than 3500 ethoxylated products and export them to various markets across the Globe. We manufacture a wide range of ethoxylates of C12 to C18 Fatty Acids, ethoxylates of C8 to C22 Fatty Alcohols, ethoxylates of alkyl phenol, castor oil ethoxylates and ethoxylates of C12 to C22 Fatty Amines. we also have the capablities to ethoxylate substrates like polyhydric alcohols to their corresponding ethoxylates.

Ethoxylate is a compound that is produced by the addition of epoxides/ethylene Oxide (EO) in desired molar ratio to substrates like alcohol, acid, amine or vegetable oils in block wise or random manner where Ethylene Oxide (EO) ranges from 1 to any number. The addition of ethylene Oxide to alcohol, acid, amine and vegetable oil can give corresponding alcohol ethoxylate, acid ethoxylate, amine ethoxylate and oil ethoxylate. Such Ethoxylate have a hydrophobic and hydrophilic part making them amphiphilic in nature. This helps them to solubilize oil in water or water in oil depending on the type of ethoxylate used in the process. Thereby ethoxylates are compounds that lower the surface tension between two liquids, between a gas and a liquid, or between a liquid and a solid. This functionality of ethoxylates gives them the term of surface-active agents.

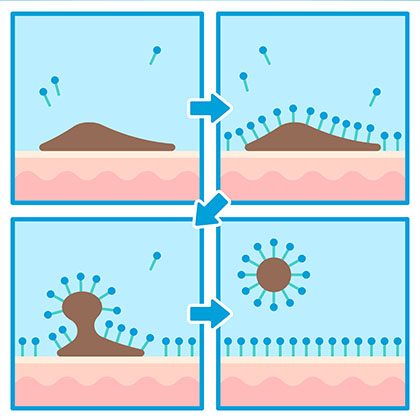

The ethoxylation process is widely used to make fatty alcohols, fatty acids, fatty amines and natural vegetable oils more soluble in water and produce surfactants which are non-ionic, anionic, cationic or amphoteric surfactants having application in different industrial application and market segment. In aqueous solutions ethoxylated surfactants form a micelle consisting of two parts, a core and a shell. The micellar structural arrangement consist of hydrophobic end groups inside the core and hydrophilic head groups are directed towards the outer shell. For example in case of fatty substrate ethoxylate, the arrangement of the hydrophilic head (ethoxylate) is at the interface of water and the hydrophobic groups (fatty substrate) align toward the oil interface. While the same ethoxylated surfactant in non-aqueous solution can arrange in the exact opposite way.

Therefore, a surfactant made from fatty substrate ethoxylate contains both a water-insoluble (or oil-soluble) component and a water-soluble component. Fatty Ethoxylates will diffuse in water and adsorb at interfaces between air and water or at the interface between oil and water, in the case where water is blended with oil. This property allows ethoxylates to act as detergents, wetting agents, emulsifiers, foaming agents, and dispersants.

Ethoxylates play an important role in personal care products such as cosmetics, shampoos, shower gel, hair conditioners, and toothpastes. The property of providing cleaning, wetting, and dispersing, emulsifying, foaming and anti-foaming effects are used in many practical applications and products. ethoxylates with different HLB are used in detergents, fabric softeners, soaps, paints, adhesives, inks, emulsions, anti-fogs, ski waxes, snowboard wax, deinking of recycled papers, in flotation, washing and enzymatic processes. Agrochemical formulations such as some herbicides, insecticides, biocides (sanitizers), and spermicides also contain ethoxylates.

Ethoxylates especially Polyethylene glycols or PEGs are used in drug delivery systems because they are neutral, nontoxic, and water soluble and can form micelles which are biocompatible and biodegradable.